Sometimes the accuracy of Draft Survey is a big question, especially when the cargo loaded or discharged from the vessel shown extremely different weight with the references Weight Scale or Counter Weight. Unfortunately, the parties concerns would be doubt on to the weight resulted by Draft Survey, as they have been relying upon the mentioned scales for many years.

Draftmark

The Draft Surveyors as the person in charge should be solve this issue to prevent any claim in the future. Where is the doubt came from? The next investigation is required to calm down these issues.

Draught Survey UN ECE: Code of Uniform Standards and Procedures

UN ECE was published the Factors Affecting Draft Survey as follows :

1- Incorrect hydrostatic information or draft marks: Investigations carried out in specially performed draft surveys have indicated that there can be significant errors in the determination of displacement due to typographical errors or arithmetical errors in the ship’s hydrostatic tables. This could be improved if the tables furnished to the

surveyorbore an approval stamp by the flag government or the classification society. A number of years careless re-painting of draftmarks, especially if they have not been permanently marked on the hull, can cause erroneous readings. If there is any doubt, the draft marks should be re-sited at the next dry-docking.

2- Incorrect tank calibrations: This is normally ascertained after a number of draft surveys when a constant error may appear. It may be verified by a carefull draft survey when just the tank(s) in question are filled or emptied with no other weight changes. Clasification societies, upon request of the shipsowners, may however issue the special calibration certificates for each compartment of the vessel.

3- Mud and/or scale in ballast tanks: The quantity of mud and/or scale will increase over a period of years, depending on the sediment in any ballast taken, on the extend of scale formation and on the cleaning which is carried out. It is very difficult to quantify. The effect on ballast calculations can be minimized unless there are reasons to the contrary by leaving a measurable quantity of water in the ballast tank instead of pumping it dry. The calculation would then use a difference in known water quantities rather than assume that a tank is completely empty : in this way the error would be confined within the density differential of the mud and the ballast water. Regularly large bulk carriers arrive at unloading ports with a slight trim by the head as a result of burning fuel from the aft located fuel tanks during long sea passages. Since generally the sounding pipes are located aft only, dry soundings of ballast tanks do then not necessarily mean that no water is present, since any water will accumulate in the fore end. When the ballast tables are subsequently entered with zero sounding and the head trim, considerable quantities of residual ballast water are found. Again, this water does not actually have to be present. Consequently, when one assumes empty or tabulated quantities, both may be wrong.

4- Bottom shell growth: Marine growth on the bottom of the ship, especially if dry docking is delayed or if there is a failure in the anti-fouling paint, adds weight to the ship. But, because this weight should not change between the start and finish surveys, it has no effect on the calculation of the cargo weight, unless the vessel is docked for a long period or the antifouling paint deteriorates.

5- Water disturbance: Normally due to wind, swell or passing traffics. Accurate reading of the draft requires the use of a draft reading tube.

6- Variations in seawater density: If a loaded vessel has a small underkeel clearance, the seawater may hold mud/sediment in suspension, or chemicals in solution could effect its density. This may be apparent from the bottom layer sample. If it is suspected, a sea water sample should be taken from the maximum draft as a check. In river ports or in proximity of river mouths or of industrial plants, there may be numerous layers of water with differing densities, which may substantially affect the accuracy of the water samples unless properly detected.

7- Vessel squat: When a vessel is moored in a tidal stream or a fast flowing current, in shallow water, it will squat in the water, i.e. its draft will increase. This is due to the fall of the pressure of the water between the bottom of the hull and the seabed. The sinkage is due to a number of complex factors due to the hydrodynamic properties of the hull, especially where underkeel clearance is small and which cannot be accurately determined by theoretical calculations. There appears to be no effect at current speeds below 2,5 knots. If conditions are inductive to squat, the surveyor and the master should monitor carefully that the vessel is fully afloat and not touching the bottom and for best accuracy, consider waiting for slack water, or shifting the vessel to another berth where the effect of squat are known to be less or absent.

8- Asymmetrical hull deflections: If the mean draft midships differs from the mean of the forward and after drafts, it is assumed that the deflection of the hull shape takes the form of a parabolic curve. This assumption is inherent in the two-thirds and quarter-mean methods of correcting for hull deflection. If there is no difference between the mean draft midships and the mean of the forward and after drafts, it is assumed that the hull shape has not been deflected. Both assumptions may be incorrect. In practice, the hull deflection may not be a parabolic curve or there may be deflections between the ends of the vessel and the midship points (i.e. as a modified sine curve). If the draft is not read at all six draftmarks, the hull may be twisted without the fact being known.

9- Solar bending: Vessels of approximate 50.000 mt deadweight and upwards, may be subject to hull deflections caused by solar bending of the deck and structure above the waterline. The effect would normally be a hogging which can be appreciable. Some readings taken on a 74.000 mt dwt bulk carrier and reported in “Seaways” (March 1987), showed that the fully loaded vessel was sagged 5 cms at 07.00 hrs and 27,5 cms at 17.00 hrs on the same day with no movement of weight within the vessel (apart from normal oil/water consumption for an anchored vessel).

10- Use of approximate methods for corrections: The mathematical methods used to correct for trim and/or hull deflections, if these conditions exist, are approximations because of limitations of time, expense and the work site. However, if the same methods are correctly and uniformly employed in all surveys, the resultant error in the exact cargo weight will be minimal. However, if in better equipped ships, correction tables for trim and/or hull deflection are available, then such tables should be used instead of the approximate methods.

11- Draught gauges: Draught gauges may be very helpful as a check, but should never replace the reading of draughts using the fixed draught marks on the ship’s hull.

12- Squat: While measures the draught, when there is a strong current running and there is water depths of less than twice the draught of the vessel, the draught readings may be misleading, due to the effects of squat. The survey report should include reference to Possible Squat Effects, even if a suitable correction to the draught readings cannot be determined.

13- Anchors and Chains: The anchors may be in the housed position, where they contribute to the lightship, or they may have been used in the mooring of the ship. Then the anchors will be on the sea bed along with a given length of cable. The loss of weight due to its removal is weight taken from the light displacement, this amount should therefore be added to the quantity of cargo. There should be information available on board to enable the surveyor to establish or calculate the weight of the missing anchor and cable.

In case of the chain cable, it can be calculated with reasonable accuracy by the following formula:

Weight per shackle (Tonne) =

15 x (link diameter in cm)2 x 3,87

——————————————

1000

The link diameter is the diameter of the steel rod, which makes up each individual link. In the case of the anchor itself, this will vary from ship to ship, but this information should be available on board. This anchor weight should be rounded to the nearest half tonne.

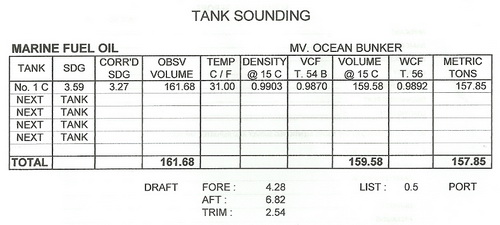

Draft Surveys – Volume And Weight Calculations:Draft Surveys are to determine the quantity of cargo loaded in, or discharged from a vessel or barge and are dependent on the fact that the vessel or barge is always afloat, and that all the drafts are visible. Some of the common problems during draft surveys one should always be aware of are:

* Unusable sounding pipe – i.e., inaccessible, blocked or broken

* Ballast holds, which are poorly calibrated

* Tunnel space/duct keel that cannot be sounded

* Loaded vessel aground prior to commencement of discharge

* Loaded vessel aground after completion of loading prior to sailing

* Listed vessel, which has its effect on displacement and soundings of liquids in tanks and other spaces

* Weights other than the cargo, ballast, or consumables that are not the same between the starting and the finishing surveys.

Surveyor’s opinion:

All the above are very clear explanations and guides. Additionally, Surveyors has concerned to Draft Mark Reading. Draft Mark reading is the essential part of Draft Survey, where the Draft Survey is begin from the reading part. The vessel’s staffs cooperation is needed to success the good reading. The following are some rules to get the best result :

- Vessel is secured properly,

- No any ship’s gears movement allowed at the time, (such as crane, derrick etc),

- No any ship’s liquids transfer activity allowed during reading, (ballast, fresh water, fuel and diesel oil),

- Read the Draft Marks as close as possible, taken pictures for the next clarifying,

- Use the small boat to read close the Draft Marks, do not see it from the ship’s maindeck,

- Find the draft in meter first then continue with centimeter to prevent big error.

- For the heavy swell sea condition it is recommended to read and record 12 times, taken out 1 biggest and 1 smallest of the reading results, and make an average draft from the 10 results remained.

Do you have any issues regards this? please drop down your comments here.